PACIFIC LINKS INTERNATIONAL

GLOBAL MANUFACTURING CENTERS OF EXCELLENCE

Pacific Links International Subsidiaries CK Swift & Company and KS Industries LLC manage manufacturing operations in Taiwan, China, Vietnam, Japan, and the USA. Our headquarters in Plano, TX USA, manages all imports and exports in and out of each Pacific Rim center of excellence. Quality control, engineering, and first article approval are controlled and maintained by the Pacific Links International headquarters in Plano, TX.

|

CENTER OF EXCELLENCE |

CNC Swiss Turned Machine Components |

CNC Machine Components |

Injection Modeling Products |

Ceramic Components |

Electrical, RF Harnesses |

Fiber Optic Harnesses and Enclosures |

Fiber Cable Manufacturing |

TAIWAN |

X |

X |

|

| X |

| |

CHINA |

|

X |

X |

X |

X |

X |

|

VIETNAM |

|

|

X

|

|

X |

X |

X |

JAPAN |

|

|

| X |

|

|

|

USA |

X |

X |

|

|

X |

X |

|

THE ONE SOURCE FOR YOUR MANUFACTURING NEEDS

VIETNAM - CENTER OF MANFUACTURING EXCELLENCE

Ha Noi, Vietnam

Complete environmental test capability

Hai Phong, Vietnam

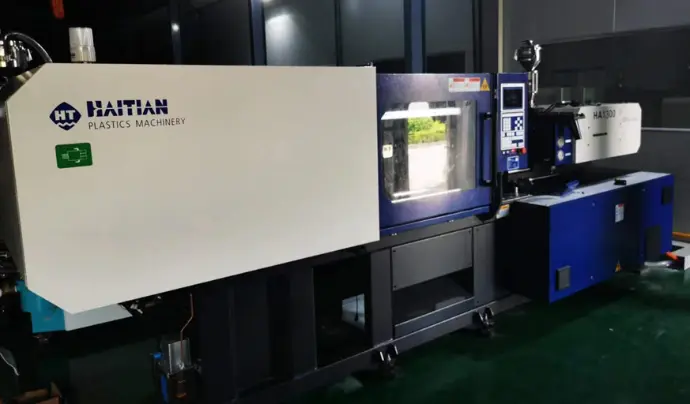

Injection Molding Production

CNC Machining and Sheet Metal Operations

Vietnam is emerging as a major player in global manufacturing, fueled by strategic government policies, competitive labor costs, and an increasingly skilled workforce. Over the past decade, industries such as electronics, textiles, and automotive production have seen significant growth, positioning our Vietnam Center of Excellence as a critical center for global production. Government initiatives, including foreign direct investment (FDI) incentives and improved infrastructure, have created an environment that supports industrial development. Today, the country's manufacturing landscape is evolving with the adoption of advanced technologies like automation, artificial intelligence, and Industry 4.0, with these innovations driving increased productivity, quality, and efficiency across various sectors.

Pacific Links International realized the value in Vietnam as a manufacturing center of excellence and made strategic investments into this county over 7 years ago. Our two dedicated cables assemblies facilities host a combined 4 cables manufacturing lines, 10 assembly lines, and dedicated assembly production for your custom cable assembly needs. We also partner with plastic injection molding, CNC, and sheet metal manufacturing centers to offer an attractive outsourcing hub for for multinational companies.

Cables Manufacturing Production

BACK

Quality Inspection Area and Cable Manufacturing Center

CHINA- CENTER OF MANFUACTURING EXCELLENCE

Pacific Links International’s manufacturing platform in China is a cornerstone of our global operations, combining cutting-edge technology, innovation, and stringent quality controls to deliver world-class OEM and ODM solutions. Our Hong Kong center serves as the hub for Research and Development (R&D), housing over 50 skilled engineers who drive the design, development, and continuous improvement of our products. All engineering for our China-based products originates here, ensuring that our offerings are at the forefront of industry advancements. With a focus on rigorous design change management, the Hong Kong team plays a pivotal role in refining our product portfolio to meet evolving customer needs and industry standards.

In Shenzhen and Huizhou, we leverage advanced manufacturing capabilities, producing a diverse range of high-performance components, including machined parts, injected molded assemblies, and fiber optic solutions. Our pilot production line is central to the innovation process, enabling rapid prototyping, process verification, and performance evaluations before full-scale production. To ensure that all products meet GR/IEC standards, our extensive testing facilities are equipped with advanced optical fiber connector testing equipment, conducting comprehensive reliability verification at every stage of production. From incoming quality control (IQC) to outgoing quality control (OQC), and from nonconformance management to customer complaint handling, our commitment to excellence is embedded in every facet of our operations.

TAIWAN- CENTER OF MANFUACTURING EXCELLENCE

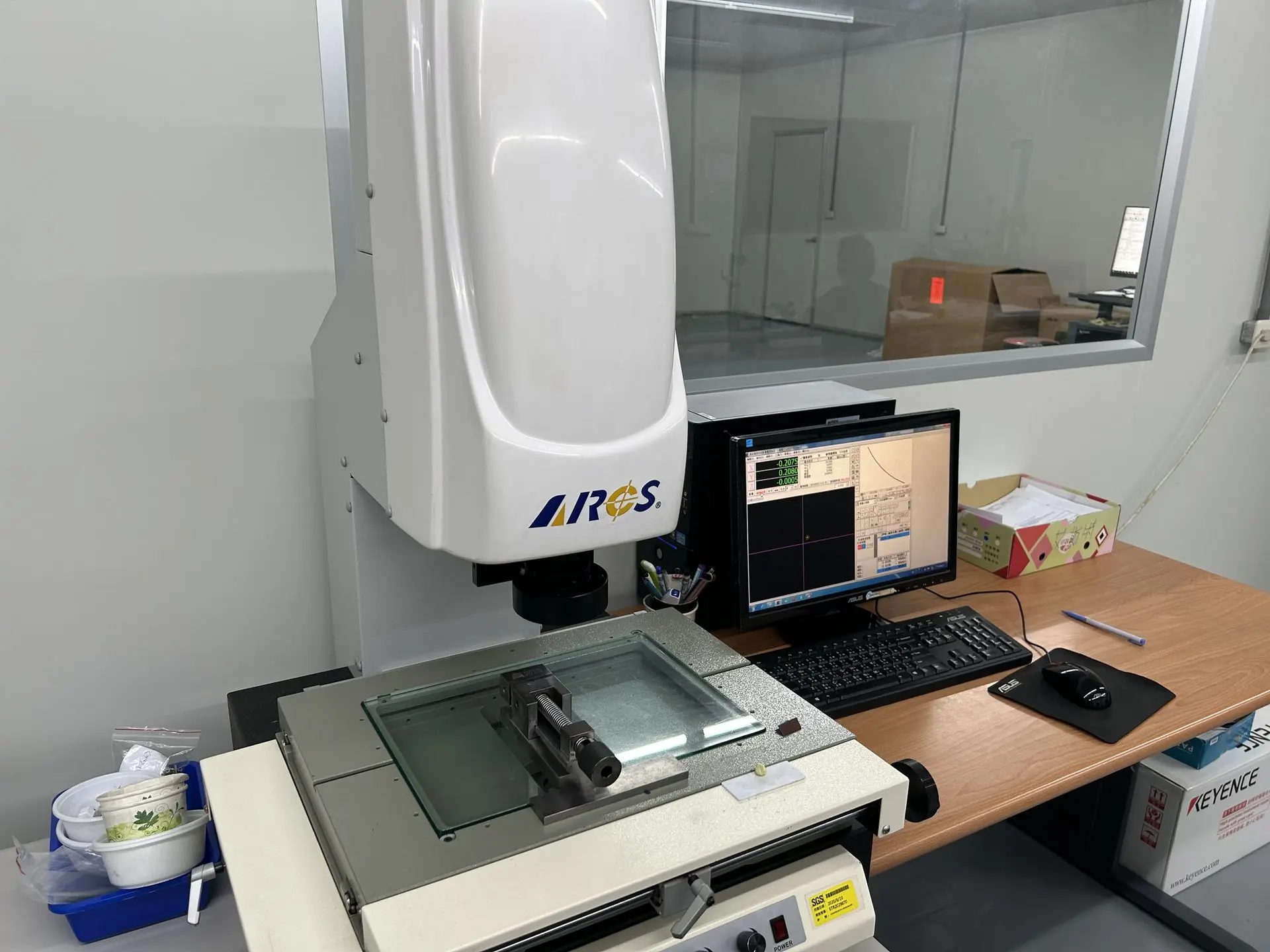

Pacific Links International stands at the forefront of global manufacturing with its centers of excellences in Taiwan, strategically located in Hsinchu and Taichung. These facilities are equipped with advanced capabilities in CNC machining, active and passive device manufacturing, and fiber optic assembly set us apart as a leader in precision manufacturing.

Our CNC machining centers are designed for high-precision operations, capable of producing complex parts with tight tolerances. At the same time, our fiber optic assembly and production operations incorporate the latest techniques for splicing, testing, and packaging, ensuring the highest standards of performance for critical communication infrastructures.

At Pacific Links International, quality is the cornerstone of everything we do. We have achieved multiple prestigious certifications, including ISO 9001, ISO 45001, ISO 14001, CPR, UL, and ROHS 2.0, underscoring our unwavering commitment to operational excellence and sustainability. With a firm belief in "Prevention first, continuous improvement," we proactively identify and resolve potential issues before they arise, ensuring the consistent delivery of products that exceed industry standards. This approach has earned us the trust of global clients across various sectors.

Taiwan CNC Manufacturing in Taichung

Hsinchu City, Taiwan

Swiss Screw Machining Operations

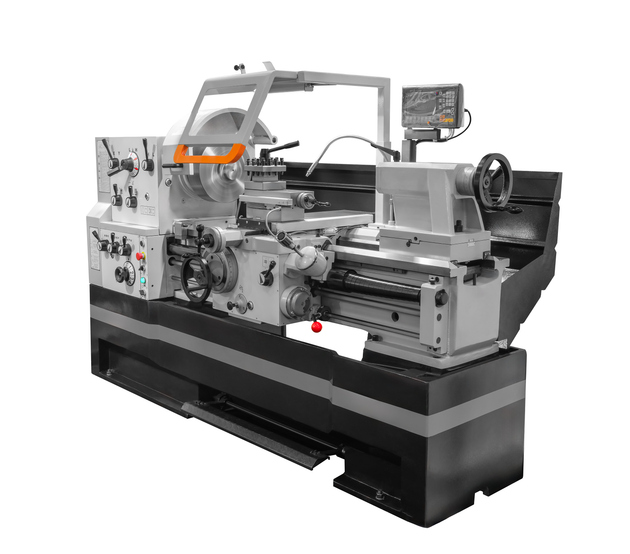

CNC Lathe Manufacturing

UNITED STATES OF AMERICA- CENTERS OF MANFUACTURING EXCELLENCE

Since our inception, Pacific Links International has been committed to investing in US domestic manufacturing centers to offer specialized manufacturing solutions to our US domestic clientele. In the domestic market, our specialties include multi axis CNC Swiss turning & CNC Swiss Micro/Miniature Machining. Our metalworking professionals produce parts for some of the most recognized company names in their respective industries.

A Swiss-type lathe is not necessarily made in Switzerland. It is a type of turning center that was developed for the Swiss watch industry. These machines are designed to turn small, complex, precision parts. Unlike conventional lathes where the part is stationary and the tool moves, a Multi Axis CNC Swiss-type turning center allows the part to move in the Z axis and the tool is stationary.

The bar stock is held in the machine and advanced through a guide bushing. Only the portion being machined is exposed from the guide bushing, allowing the material to be held tightly, virtually eliminating deflection — and increasing accuracy.

These features allow complete machining in a single operation. Although conventional CNC lathes can perform C axis live tool work, the unique design of Multi Axis CNC Swiss-type machines gives the user more capabilities with greater accuracy.

JAPAN - CENTER OF MANFUACTURING EXECELLENCE

CERAMIC PRODUCTS

Ceramic ferrules are precision components used in fiber optic connectors to align and hold optical fibers in place. Made from high-quality materials like zirconia, these ferrules are essential for ensuring low insertion loss and high-quality signal transmission in fiber optic connections. Pacific Links International specializes in producing these ferrules with strict adherence to industry standards for precision and durability.

Aerospace Applications

Aerospace Applications Electronic Device Applications

Electronic Device Applications Telecommunications Applications

Telecommunications Applications Biomedical Applications

Biomedical Applications Industrial Applications

Industrial Applications Datacenter Applications

Datacenter Applications