PRODUCTS

GREAT PRODUCTS, TRUSTED PARTNER

Pacific Links International combines "best in class" manufacturing capability with cost-effective offshore manufacturing centers strategically located throughout the Pacific Rim and North America. Our business goal is to offer a wide variety of offshore manufacturing options to provide cost-effective "first article" or low-rate production components and overcome "bottlenecks" in the supply chain.

CNC SWISS TURNING PRECISION MACHINING

CNC Swiss turning is a specialized machining process that allows for the creation of highly accurate, complex parts with tight tolerances. This technique is particularly useful for manufacturing small, intricate components, such as fiber optic connectors, ferrules, and other precision parts needed in the telecommunications industry. Pacific Links International likely utilizes this process to produce parts that demand high precision and repeatability.

LEARN MORE

CUSTOM INJECTION MOLDED COMPONENTS

We thrive at providing custom injection molded components. Our tool development process is world-class, and we accelerate at both small- and large-scale production of injected molded components

CNC MACHINING

CNC machining is a manufacturing process where computer-controlled machines are used to produce parts with high precision. It’s ideal for creating complex parts with detailed specifications, such as custom housings for fiber optic assemblies, enclosures, and connectors. Pacific Links International may leverage CNC machining to produce high-quality components that meet the exacting standards of their clients.

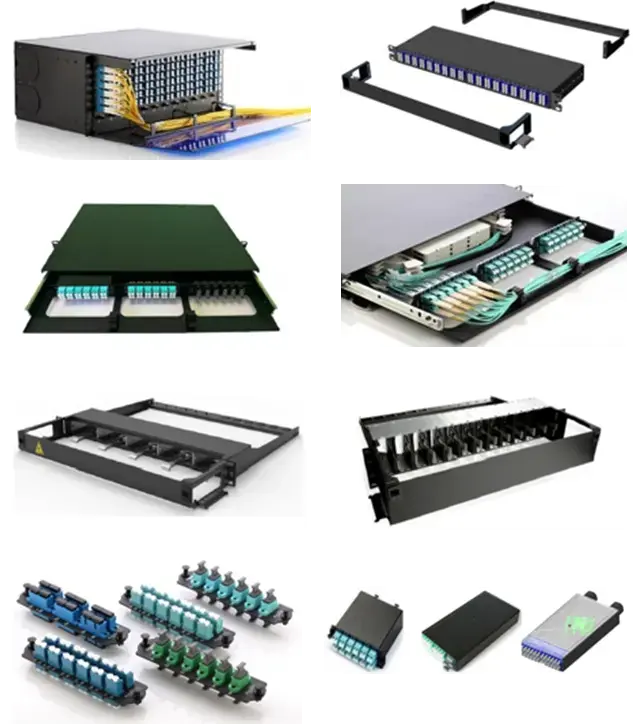

FIBER OPTIC ENCLOSURES, PANELS AND MODULES

Pacific Links International offers a comprehensive range of fiber optic enclosures, designed for superior cable management and network efficiency. Our product lineup includes Fiber Optic Slide Trays, Fiber Optic Cassette Single Mode, Fiber Optic Sliding Panels, and Blank Fiber Optic Adapter Panels. Each enclosure is constructed from top-tier industry materials, ensuring durability and reliability in demanding network environments. For ease of installation and organization, our enclosures come equipped with cable holders, mounting screws, and cable ties. Engineered for high performance, these enclosures support structured cabling solutions and comply with ISO/IEC 11801 standards, making them them ideal choice for data centers, telecom networks, and enterprise applications.

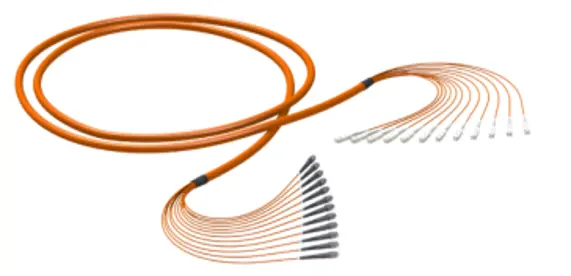

TURN-KEY FIBER OPTIC HARNESSES & ASSEMBLIES

Pacific Links International is a premier manufacturer of turn-key fiber optic harnesses, multi-fiber assemblies, pre-assembled optic cassettes and cartridges, fiber optic enclosures, cassettes, and patch panels. The company offers a wide range of fiber optic enclosures, including Fiber Optic Slide Trays, Fiber Optic Cassette Single Mode, Fiber Optic Sliding Panels, and Blank Fiber Optic Adapter Panels.

We are fully compliant with ISO/IEC 11801 standards, specializing in OM1, OM2, OM3, OM4, and OM5 fiber optic assemblies.

CERAMIC FERRULES AND SLEEVES

Ceramic ferrules are precision components used in fiber optic connectors to align and hold optical fibers in place. Made from high-quality materials like zirconia, these ferrules are essential for ensuring low insertion loss and high-quality signal transmission in fiber optic connections. Pacific Links International may specialize in producing these ferrules with strict adherence to industry standards for precision and durability.

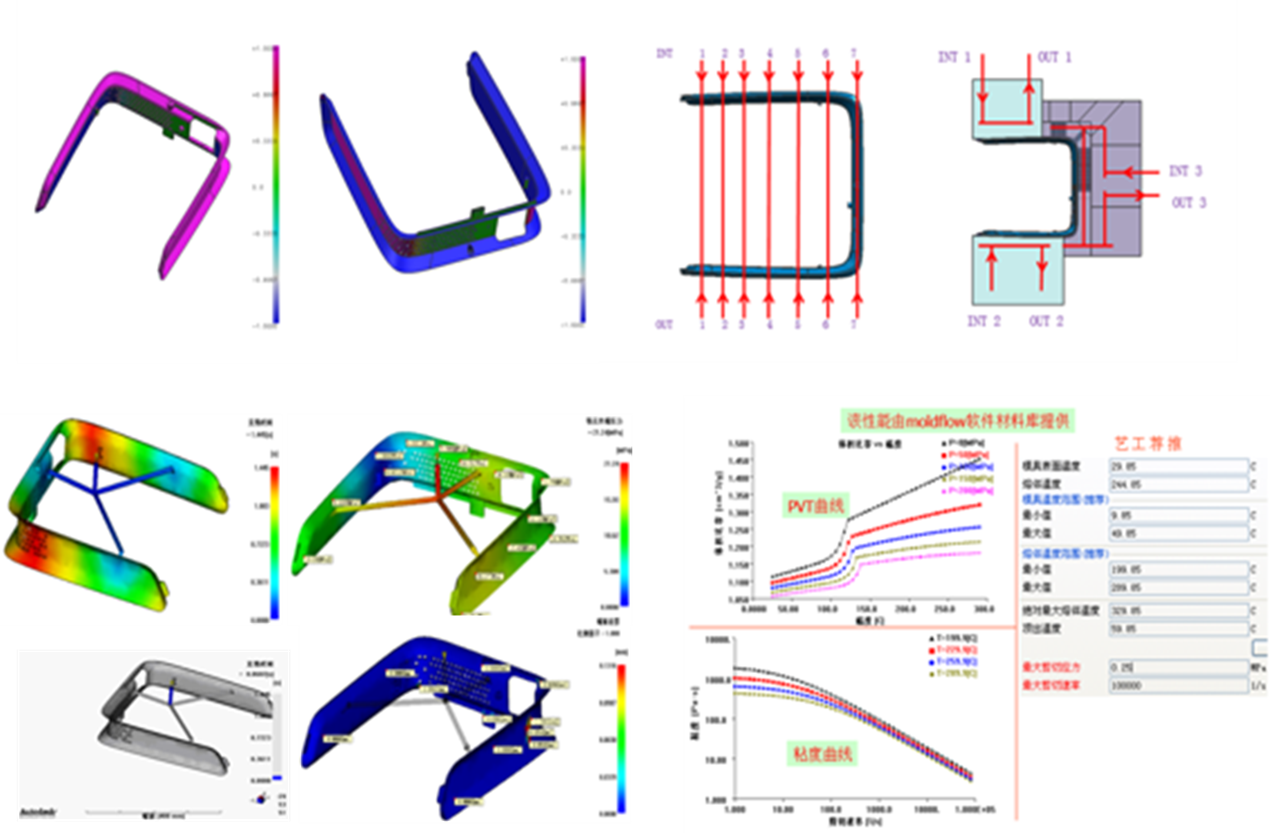

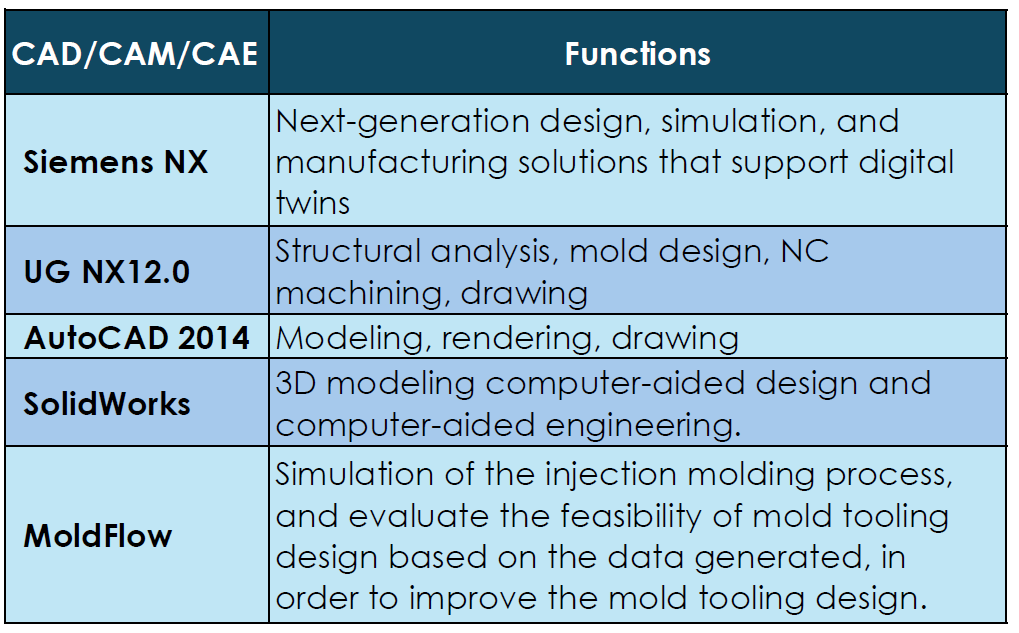

INJECTION MOLDING TOOL DEVELOPMENT

BACKGROUND

In the world of manufacturing, precision is paramount, and Pacific Links International is positioned at the forefront of delivering high-quality injection molding solutions. With a proven track record and a commitment to innovation, Pacific Links International specializes in producing complex, high-tolerance parts that meet the most demanding specifications. Leveraging advanced CAD, CAM, and CAE software such as Siemens NX, UG NX12.0, AutoCAD 2014, SolidWorks, and Moldflow, Pacific Links International bring your designs to life with unmatched accuracy and efficiency. Pacific Links International maintains a fully staffed mold tooling factory complete with mold design software, engineering team and the necessary CNC, EDM machines to produce precision molds

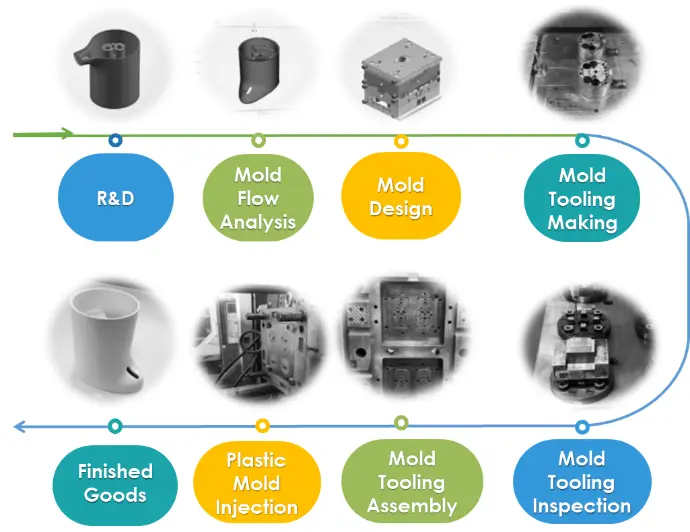

MOLD TOOL DESIGN AND MANUFACTURING

Our tool engineering and design process follows a stringent gate process for quality molded components. All components are researched for ease of production, mold flow analysis, design, before the tool is manufactured.

TOOL DEVELOPMENT PROCESS

LARGE SCALE INJECTION MOLDED COMPONENT PRODUCTION

Pacific Links International believes that the best results come from close collaboration with our clients. Our design and engineering teams work hand-hand with you, providing expert guidance and support throughout the entire process. Using advanced software tools, we can simulate and analyze the molding process to optimize designs before production even begins.

EXCEPTIONAL QUALITY

We employ rigorous quality control measures, utilizing three-dimensional measuring equipment and altimeter measuring equipment to verify the precision of every part we produce. From the initial design phase to the final product, our attention to detail is second to none. Our mold injection machines are calibrated to deliver consistent, high-quality results, ensuring that every part meets your exact specifications.

CUTTING-EDGE TECHNOLOGY FOR SUPERIOR RESULTS

Our state-of-the-art facilities are equipped with the latest in CNC milling machines, precision milling machines, high-speed carved CNC, CNC lathe machines, EDM spark machines, mirror spark machines, and wire cutting machines—both medium and slow. These tools, combined with our expertise, ensure that every mold we produce is crafted to perfection. Whether it's deep hole drilling, laser welding, or pore discharge mac

Injection Mold Tool development applied all leading-edge mold tool CAD, CAM, CAE software platforms including Siemens NX, UG NX 12.0, AutoCAD. SolidWorks and Moldflow

INJECTED MOLDED COMPONENTS

CUSTOM MACHINED AND FABRICATED COMPONENTS

CNC SWISS TURNED MACHINED COMPONENTS

BACKGROUND

A Swiss-type lathe is not necessarily made in Switzerland. It is a type of turning center that was developed for the Swiss watch industry. These machines are designed to turn small, complex, precision parts.

Unlike conventional lathes where the part is stationary and the tool moves, a Multi Axis CNC Swiss-type turning center allows the part to move in the Z axis and the tool is stationary.

The bar stock is held in the machine and advanced through a guide bushing. Only the portion being machined is exposed from the guide bushing, allowing the material to be held tightly, virtually eliminating deflection — and increasing accuracy.

These features allow complete machining in a single operation. Although conventional CNC lathes can perform C axis live tool work, the unique design of Multi Axis CNC Swiss-type machines gives the user more capabilities with greater accuracy.

CUSTOM FIBER OPITC ASSEMBLIES, ENCLOSURES AND CARTIGIES

BACKGROUND

At Pacific Links International, our manufacturing capacity stands as a testament to our commitment to excellence and scalability. We proudly operate two highly efficient production sites in Vietnam, each equipped to handle substantial volumes of fiber optic assemblies. Our Vietnam site leads the charge with a robust capability of producing up to 3 million simplex/duplex jumpers and 240,000 multi-channel pregerminated assemblies monthly. Complementing this, our second Vietnam site contributes with 1.5 million simplex/duplex jumpers and 100,000 multi-channel assemblies per month. Additionally, our expertise in MTP/MPO termination is reflected in our capacity to deliver 200,000 terminations, each month. This extensive manufacturing capability ensures that we can meet the diverse and evolving needs of our global clientele while maintaining high standards of quality and efficiency.

UNCOMPROMISING QUALITY, PRECISION AND ENGINEERING

Engineering and testing are at the heart of our innovation strategy at Pacific Links International. Our R&D team, consisting of over 50 skilled professionals, is dedicated to advancing our product offerings through rigorous development and design change management. We leverage state-of-the-art product tooling, process development, and verification capabilities to deliver cutting-edge OEM and ODM solutions.

Our pilot production line plays a crucial role in designing and manufacturing new products, conducting process verification, and evaluating performance. With an extensive array of test equipment related to optical fiber connectors, we ensure that all products meet GR/IEC standards through comprehensive reliability verification. Our collaborative efforts with government entities and educational institutions further fuel product development and innovation, reinforcing our commitment to delivering high-quality, reliable fiber optic assemblies.

CUSTOM SIMPLEX, DUPLEX AND MULTI-CHANNEL ASASEMBLIES (OM1, OM2, 0M3, 0M4, OM5)

Single mode Trunk Assemblies

Military Eight Fiber Channel Assemblies

CUSTOM PRE-TERMINATED FI BER OPTIC ENCLOSURES AND CASSETTES

FIBER OPTIC CERAMIC COMPONENTS

Pacific Links International ferrule and sleeve products are highly regarded as worldwide international standards. Fiber breakage during fiber insertion into the back opening of the ferrule can be drastically reduced by our original molding technology. The zirconia ferrules and sleeves are our main products of fiber optic components, suitable for high end performance and quality for various fibers, connectors and device terminations.

Our zirconia ferrules are divided into 4 categories, single-mode, multi-mode, capillary and custom as well as other custom zirconia products with various shapes not associated with the fiber optic industry. Pacific Links International zirconia ferrules and sleeves are designed at our head offices in Tokyo, Japan and manufactured at our own factories based on a thorough production and quality control systems. All of our ferrules are inspected for outer diameter, inner diameter and concentricity by our proprietary inspection measurement gauges and methods.

Pacific Links International's Low Loss Ferrule revolutionizes fiber-optic performance by achieving unparalleled concentricity accuracy and inner diameter tolerance, far surpassing standard single-mode zirconia ferrules. Our proprietary injection molding technology drastically reduces fiber insertion loss, ensuring superior connectivity with minimal signal degradation.

By integrating in-house molding, precision secondary processes, and rigorous inspections, we deliver high-quality, high-performance ferrules at unbeatable industry prices. The Low Loss Ferrule minimizes clearance between the fiber and ferrule, cutting concentricity deviation in half, enabling ultra-low insertion loss for seamless, high-efficiency communication.

Pacific Links International’s Zirconia Capillaries ensure precise alignment and seamless connectivity for optical devices and modules. Manufactured using the same advanced injection molding process as our ferrules, they deliver unmatched stability and performance.

Beyond standalone capillaries, we offer integrated solutions with metal housings and ferrule assemblies, press-fitted into highly weldable stainless steel (SUS 304, 403, 316, L Metals). Available in various OD configurations (φ1.8mm–φ3.0mm), we also specialize in dual-hole capillaries, optimized for high-precision optical switches and filter-integrated devices.

Pacific Links International's Long Ferrules come in φ2.5mm and φ1.25mm outer diameters, with customizable lengths and hole sizes. We offer precision-engineered ferrule designs, including grooved variants for seamless integration with filters and specialty optical fibers. Our small-hole diameter ferrules extend beyond communications, enabling high-performance solutions for small-diameter clads and diverse applications.

Using our proprietary injection molding technology, we produce high-spec bowling-type ferrules that drastically reduce fiber insertion loss. We also specialize in custom multi-core, variable ID/OD, and uniquely shaped ferrules, tailored to meet exact customer specifications for next-level optical performance.